TechMagazín

Nano stretch film – the new generation of packaging without compromise

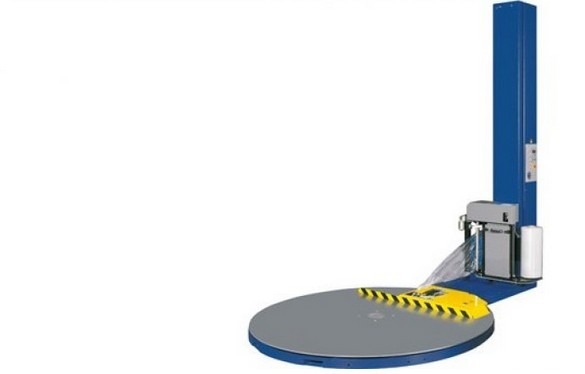

At a time when the pressure for material savings, sustainability and process efficiency is increasing, a solution is coming to market that is changing the way pallets are packaged: nano stretch film. This modern packaging material represents a breakthrough in manual and machine packaging – and proof that advanced technology can be environmentally friendly, economical and reliable at the same time.

What makes nano stretch film special

At first glance, it looks like a regular stretch film. But you’ll know the difference as soon as you use it. Nano stretch film is made up of several extremely thin layers of polymers that achieve exceptional strength, flexibility and adhesion thanks to nanotechnological manufacturing.</p

Result?

-

Up to 50% less material consumption with the same goods provisioning.

-

Lower roll weight and easier handling.</p

-

Stable, tear-free packaging, even with thinner film.

Nano stretch film thus fully replaces conventional stretch film – without compromising on protection and load stability.

Efficient and sustainable choice

Due to its high elasticity and strength, the film can be stretched significantly more than conventional types, reducing consumption and increasing packaging efficiency. It is available for both handheld and machine applications, so it adapts to any size operation.</p

The move to nano stretch film is a natural step towards more efficient and environmentally friendly packaging. Companies confirm material savings, lower waste weight and better work ergonomics. In addition, the film is fully recyclable, meeting all the requirements of modern sustainable logistics.

Technology that gives security

Nano stretch film is not an experiment – it’s a proven technology that is already helping businesses across Europe pack smarter. Every pallet is safely protected – with less consumption, lower costs and less impact on the environment.