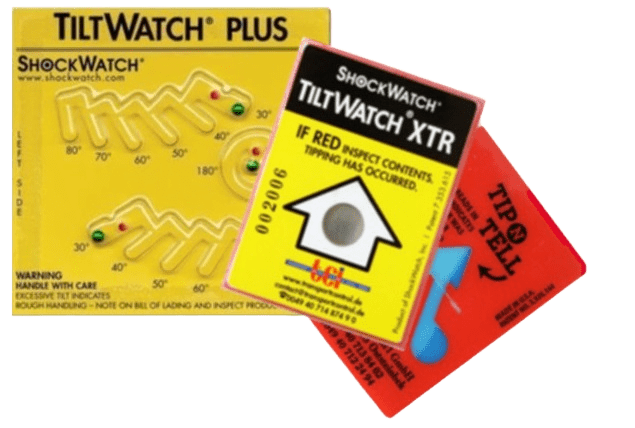

Anti-corrosion packaging

Anticorrosive Packaging – Corrosion Protection for Metal Components

Anticorrosive packaging are special protective materials designed to prevent corrosion of metal products during transport and storage. They use VCI (Volatile Corrosion Inhibitor) technology, which releases volatile corrosion inhibitors to form an invisible protective layer on the metal surface.

Main Features:

✅ Effective corrosion protection without the need for oiling or lubrication

✅ Suitable for a wide range of metallic materials (iron, steel, copper, aluminium, etc.)

✅ Eco-friendly and recyclable solution

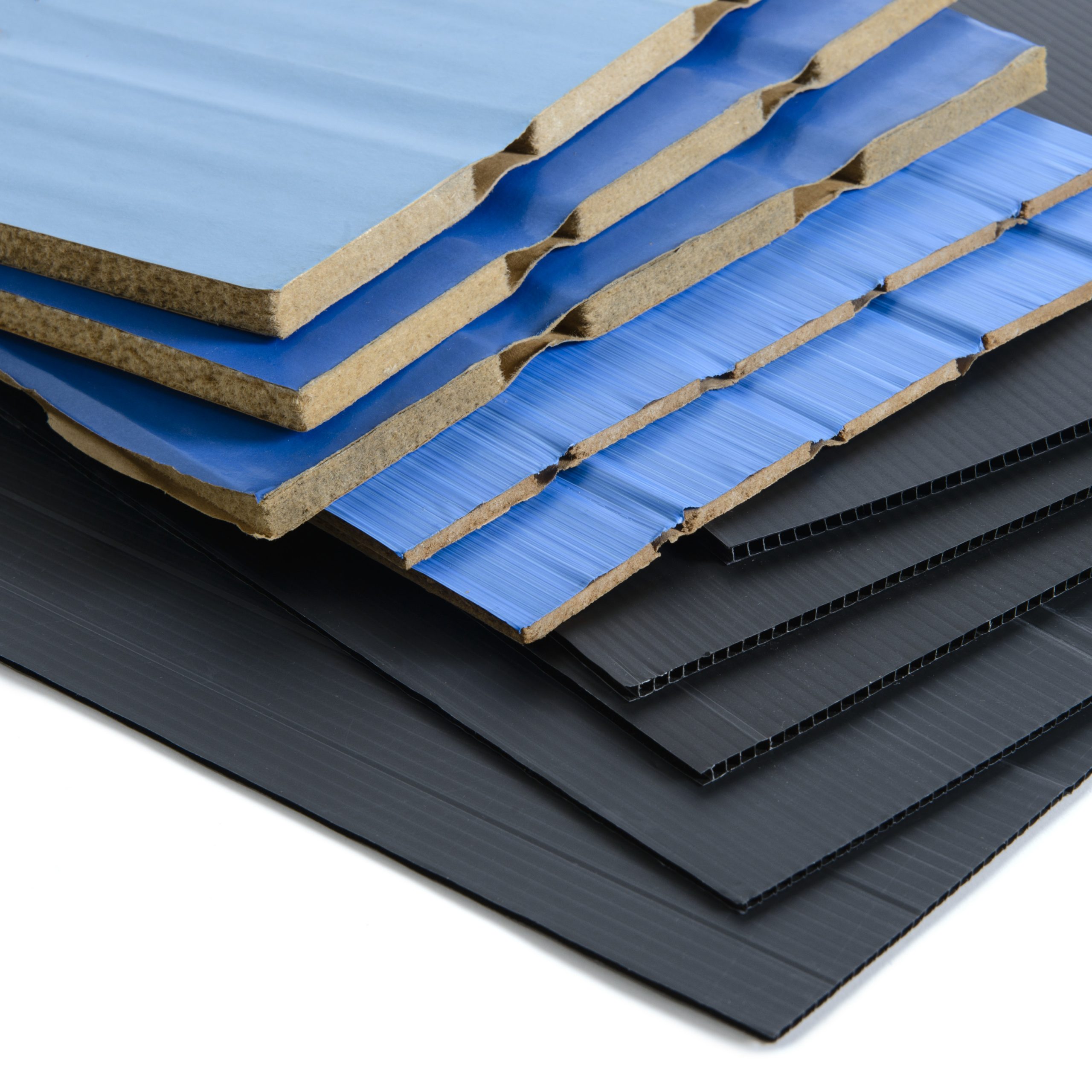

✅ Available in various forms: films, papers, bags, sacks, boxes

Use:

📦 Protection of metal components in automotive, engineering and electrical industries

🚢 Safe packaging for long term storage and export shipment

🔩 Ideal for packaging individual parts and complete assemblies

These corrosion-resistant packaging solutions provide long-term protection of metals from moisture, oxygen and aggressive substances, extending product life and reducing maintenance costs.

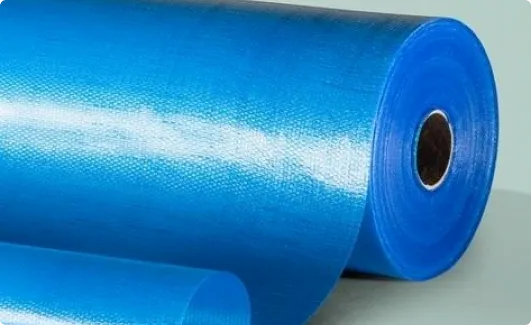

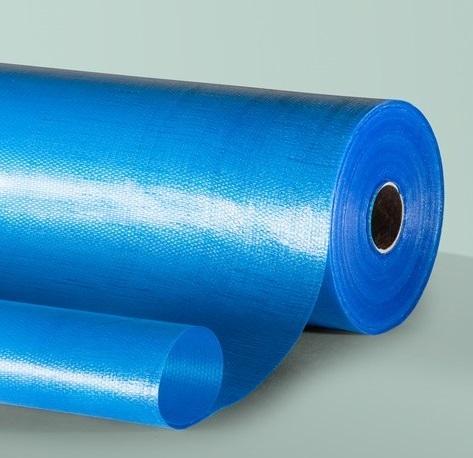

Anti-corrosion roofing foil ANTICOfol® – VCI roofing foil

Anti-corrosion roofing foil ANTICOfol® – VCI roofing foil

ANTICOfol® anti-corrosion stretch film is specially developed for the safe and strong wrapping of metal parts that require protection against corrosion and mechanical damage.

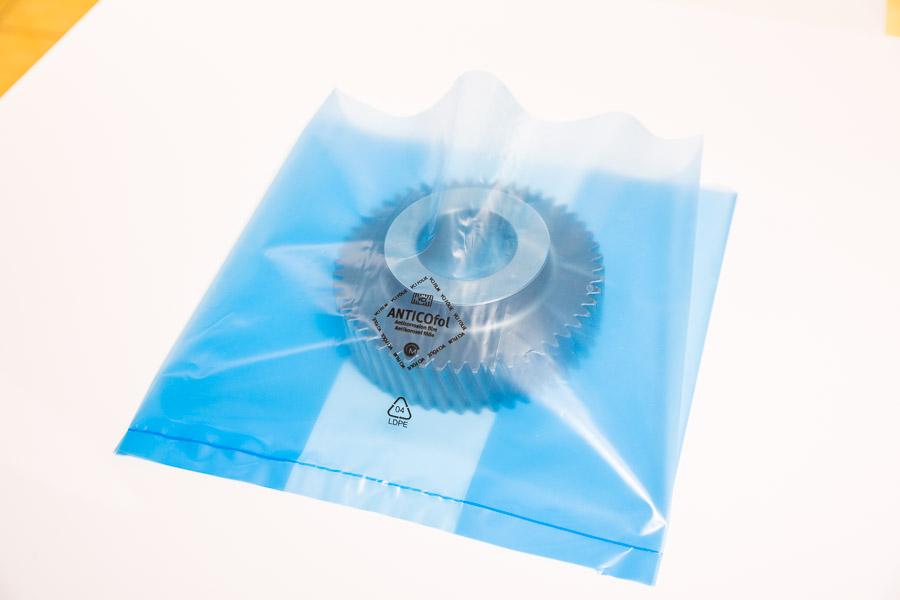

Anti-corrosion packaging film ANTICOfol®PR – VCI film

Anti-corrosion packaging film ANTICOfol®PR – VCI film

ANTICOfol® PR is a multi-layer anti-corrosion film designed for the safe packaging of metal products. It combines high mechanical resistance with modern VCI technology (Volatile Corrosion Inhibitors), which creates a protective atmosphere around metal parts - without the need for direct contact with the film and without oiling.

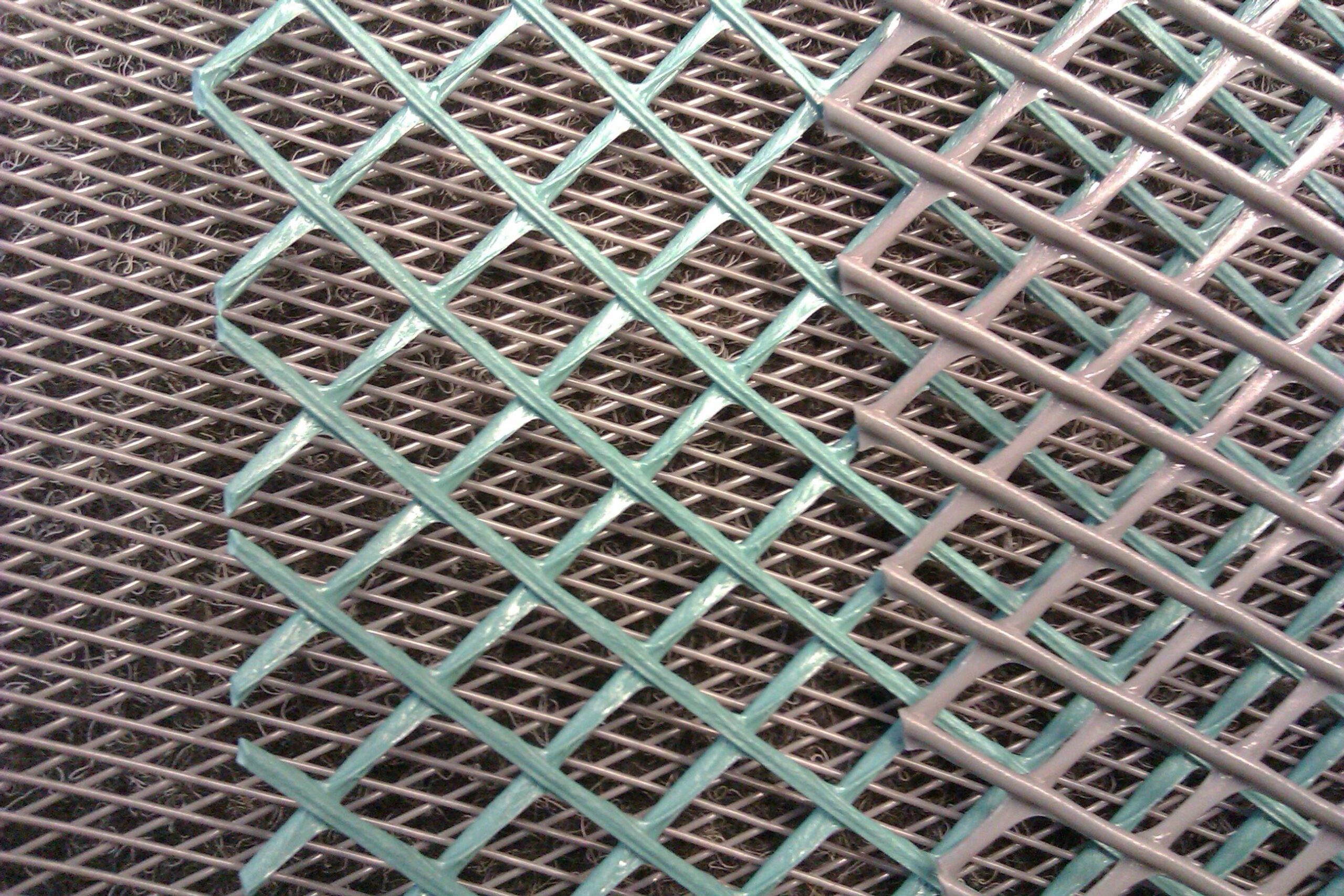

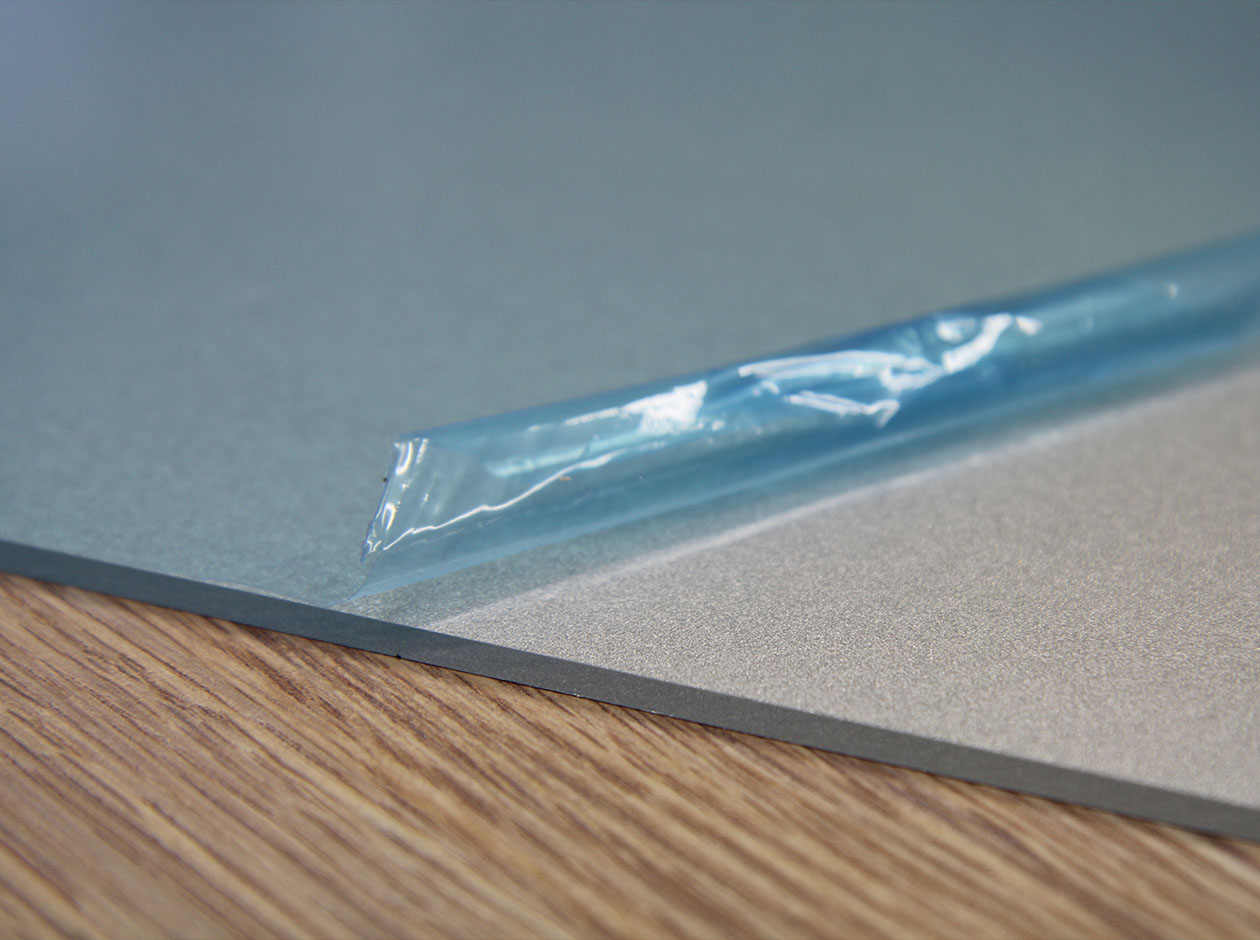

Anti-corrosion foil ANTICOfol® – VCI foil

Anti-corrosion foil ANTICOfol® – VCI foil

ANTICOfol® film contains VCI corrosion inhibitors - special substances that are released from the film and create a protective environment around the metal product. This prevents rust and oxidation without the need for lubrication or oiling.

Automatically created concept

Automatically created concept

ANTICOfol® film contains VCI corrosion inhibitors - special substances that are released from the film and create a protective environment around the metal product. This prevents rust and oxidation without the need for lubrication or oiling.

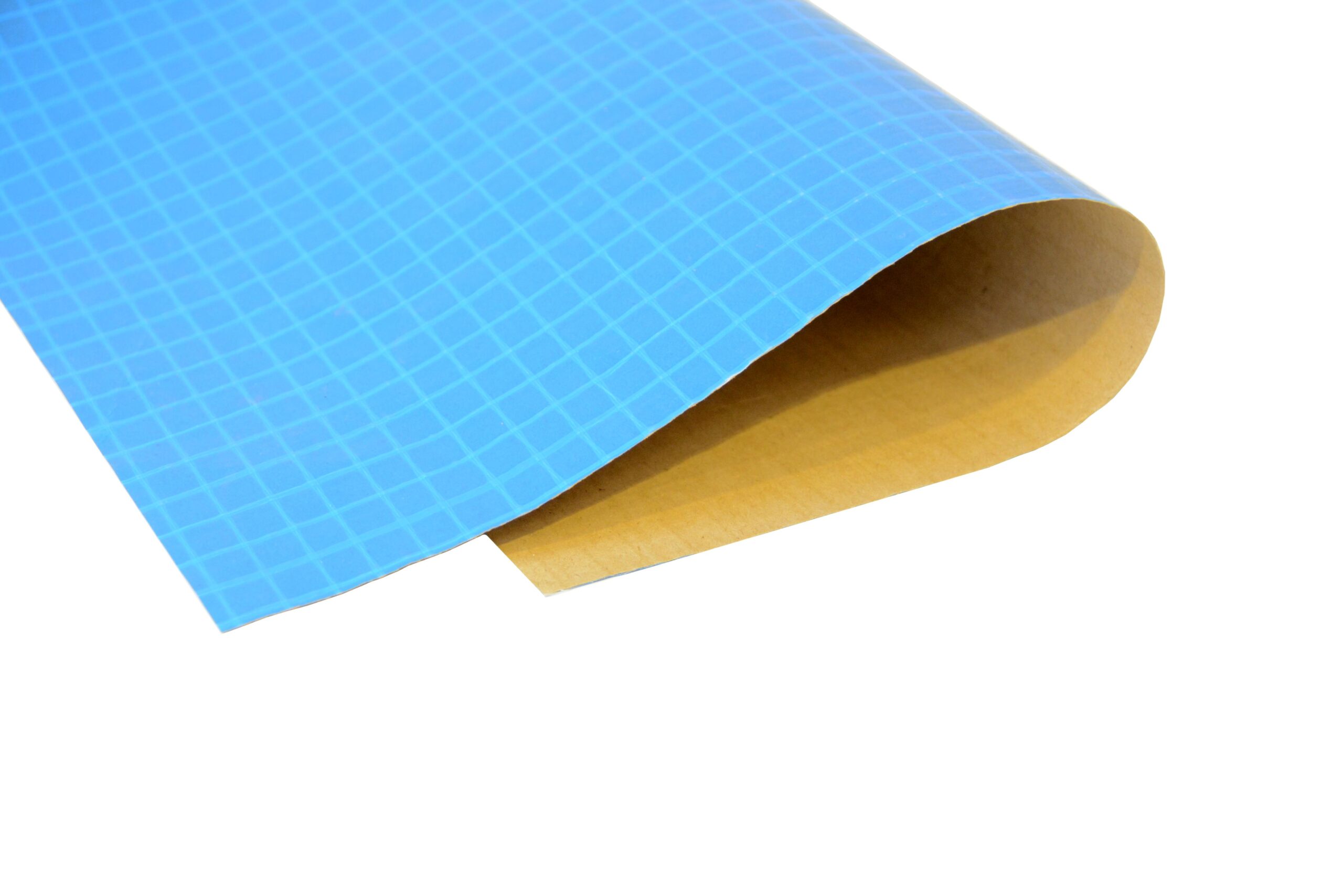

Anti-corrosion paper MULTIferro® PUK120

Anti-corrosion paper MULTIferro® PUK120

MULTIferro® PUK120 is a crepe anti-corrosive paper with one-sided effect. The paper is especially designed for the protection of copper products and copper alloys where oxidation produces the typical green coating. However, it is also suitable for other metals. The crepe structure makes it flexible, malleable and more moisture absorbent, which increases the protection of the wrapped parts.

Automatically created concept

Automatically created concept

MULTIferro® CU90 anti-corrosion paper is a special packaging material used to protect metal products from corrosion. This type of paper is particularly suitable for copper and its alloys which are prone to oxidation - typically manifested by a green colour. By comparison, iron corrodes red, while aluminium oxidises grey (but this is not classic corrosion).

MULTIferro®Chips

MULTIferro®Chips

MULTIferro®Chips is a functional cellulose plate saturated with VCI inhibitors in various sizes, which is used as a packaging supplement and serves as corrosion protection. It therefore belongs to the category of anti-corrosion packaging. Metal products can therefore be packed dry without prior preservation or passivation, as MULTIferro® Chips provide corrosion protection.

Anti-corrosion paper MULTIferro® PEK120

Anti-corrosion paper MULTIferro® PEK120

MULTIferro® PEK120 Anti-Corrosion Paper is a single-sided crepe paper impregnated with VCI inhibitors that protect metal parts from corrosion - without the need for oiling or other preservation. The paper is reinforced with a layer of polyethylene (PE), which increases its resistance to water and moisture. The crepe structure makes it flexible, absorbent and conforms well to different product shapes.

Anti-corrosion paper MULTIferro® K120

Anti-corrosion paper MULTIferro® K120

Anti-corrosion paper MULTIferro® K120 Flexible crepe paper with VCI inhibitors for double-sided protection of metal parts against corrosion - without oiling. The crepe structure makes it absorbent, easy to shape and suitable for heavier components. Health friendly, nitrite and heavy metal free. Flexible and environmentally friendly solution for safe packaging of metal products.

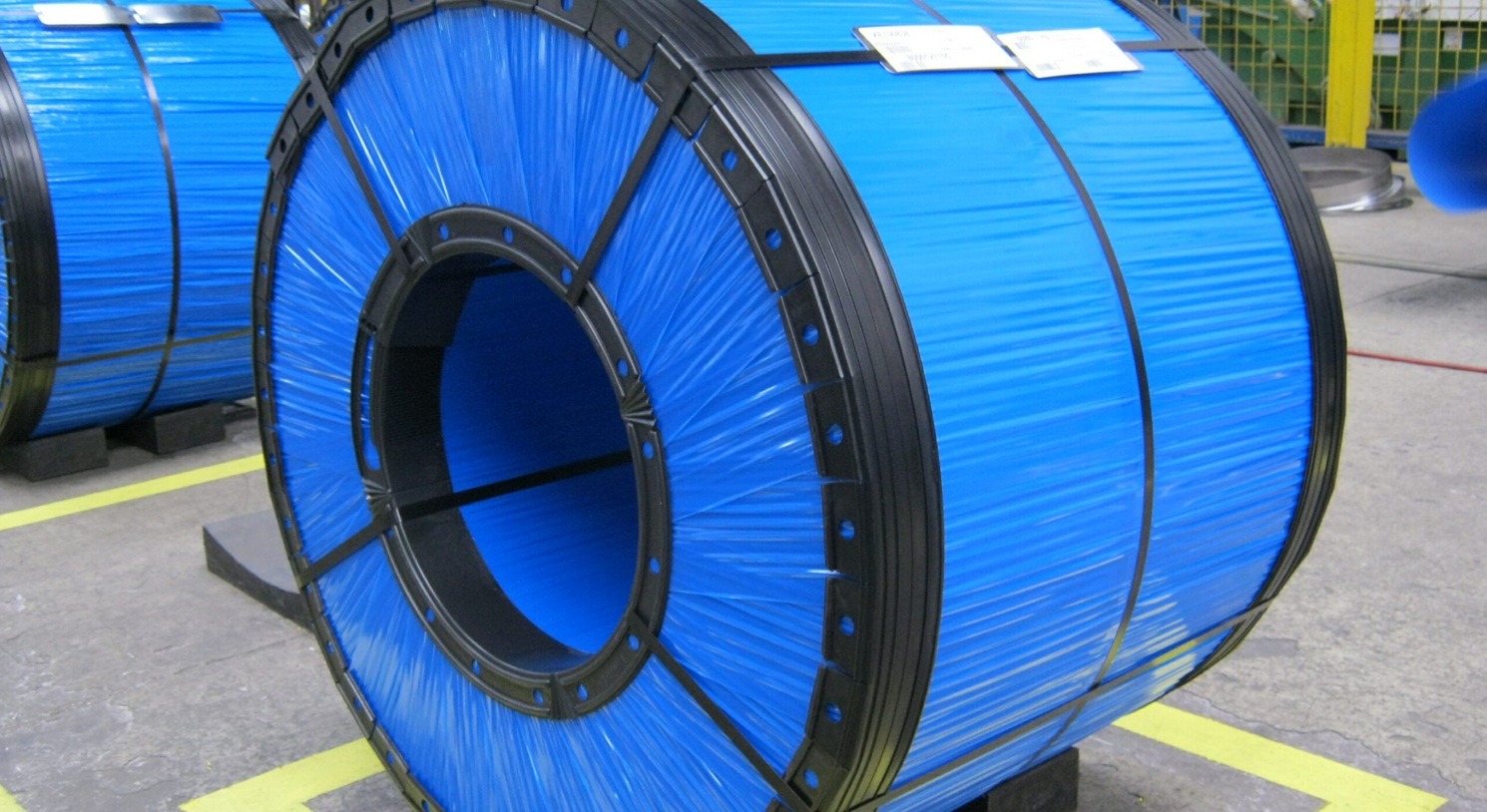

Anti-corrosion paper MULTIferro® PX145

Anti-corrosion paper MULTIferro® PX145

MULTIferro® PX145 is used primarily for packaging coils, sheets and other large metal products where a combination of high strength and reliable corrosion protection is required. The inhibitors are non-toxic, nitrite and heavy metal free.